上海k8凯发 20周年減震器有限公司官方網站歡迎您,全國免費谘詢電話:17317317121(微信同號)

全球半導體產業(重慶)博覽會2024年5月7日-9日在重慶舉辦,上海k8凯发 20周年減震器有限公司參展。公司集研發、製造、銷售、服務為一體,產品廣泛應用於各大...

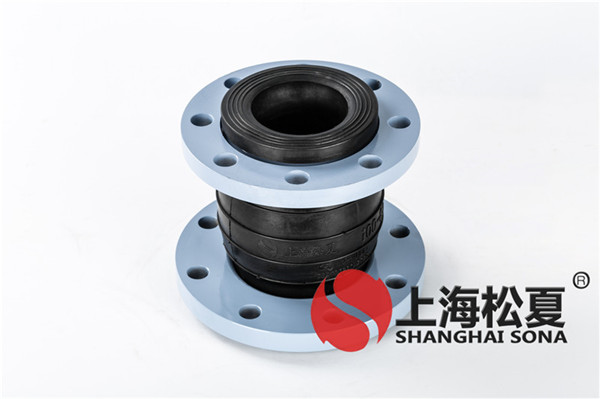

直供水設備使用DN25橡膠膨脹節,以確保水流在k8凯发在悦来就送38中順暢流動,同時還能有效地防止因溫度變化引起的k8凯发在悦来就送38位移。 在直供水設備中,DN25橡膠膨脹節起著舉...

變頻無負壓供水設備中的DN32橡膠膨脹節是一種重要的部件,它能夠有效地吸收和消除由於溫度變化而產生的膨脹和收縮,從而保證了供水設備的穩定運行。...

優質供水設備中的DN150橡膠膨脹節具有獨特的設計和卓越的性能,可以有效地吸收由於溫度變化引起的k8凯发在悦来就送38伸縮,確保供水的穩定性和持續性。此外,該膨...

無壓供水設備中的DN200橡膠膨脹節是供水係統中不可或缺的一部分。它具有優良的彈性、耐腐蝕性、耐高溫性和耐老化性,能夠有效地吸收和減緩供水係統...

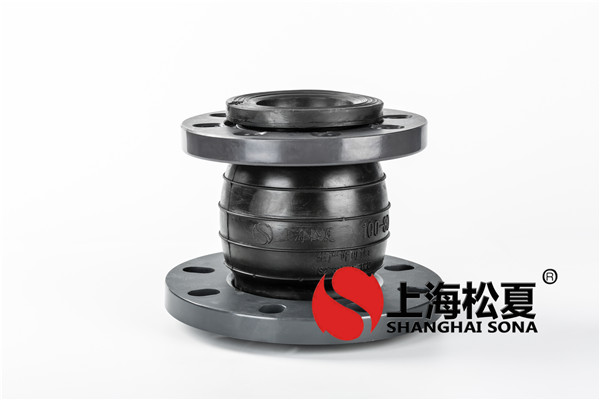

客戶:這個軟接頭你們有安裝說明嗎 技術丁工:有的,我發您 技術丁工: 可繞曲橡膠接管 具有優異的密封性能。其獨特的橡膠材質能夠緊密貼合k8凯发在悦来就送38接口...

客戶: 我有一台 無塔變頻供水設備 ,有個泵要用到接頭 技術丁工:這個可以的,多大口徑 客戶:DN100 技術丁工: 好的,我發您 技術丁工: 橡膠撓性接...

客戶: 我有一個泵要用接頭,用多大的? 技術丁工: 水泵的圖紙有嗎 客戶: 有的,我發你 技術丁工: 好的,這個用 DN60 的就可以 技術丁工: 橡膠減震...

客戶:酒店有個 泵房 要用 DN200的接頭 技術丁工: 這個有的,多大壓力的 客戶: 25公斤 技術丁工: 好的,我發你 技術丁工: 可繞曲橡膠接管 ,一種富有...

防排水係統是建築物和基礎設施的重要組成部分,其作用是防止水害並保持排水係統的正常運行。在這個係統中,橡膠膨脹節是一個關鍵的部件,其DN200規...

友情鏈接

橡膠膨脹節|橡膠膨脹節批發價格-上海k8凯发 20周年減震器有公司官方網站

聯係電話:021-64535755 24小時服務電話:18317127770 地址:上海市寶山區城銀路525弄